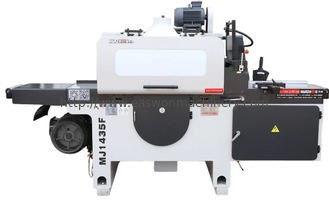

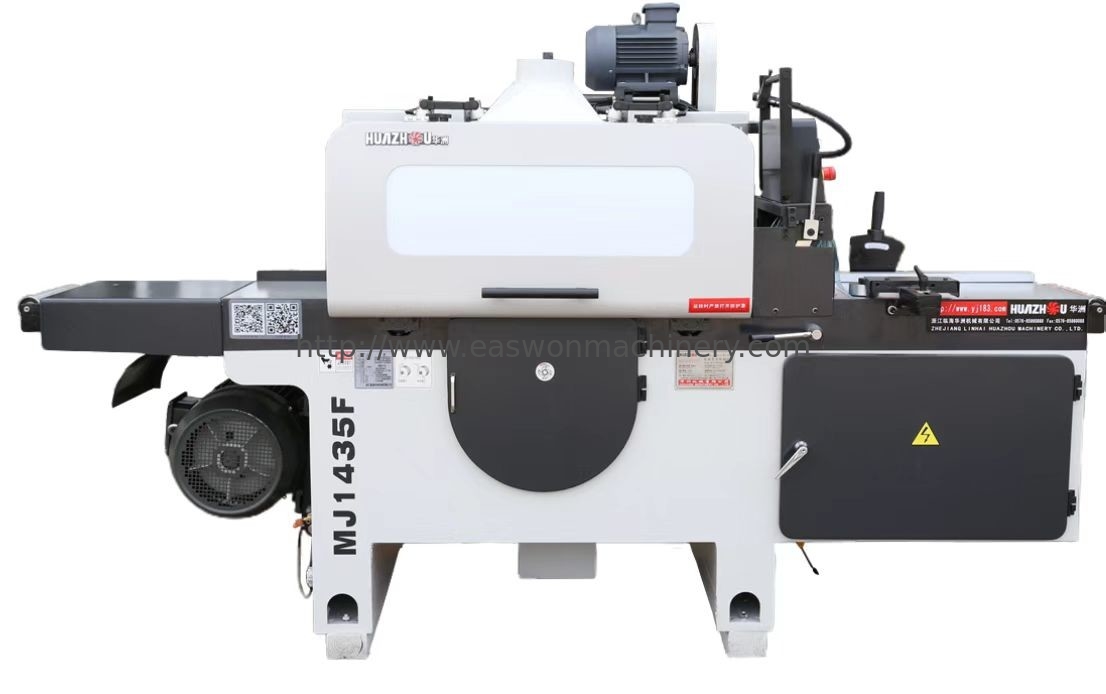

Automatic Multiple Rip Saw Machine For Processing Solid Wood Panel

Product Details:

| Place of Origin: | China |

| Brand Name: | Easwon |

| Certification: | CE |

| Model Number: | MJ1435F |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiated |

| Packaging Details: | wooden case |

| Delivery Time: | 20 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Model: | MJ1435F | Min. Sawing Length: | 550mm/360mm |

|---|---|---|---|

| Max. Sawing Width: | 300mm | Max. Sawing Thickness: | 100mm |

| Saw Blade Size: | 250-355mm X 70mm | Main Motor Power: | 26.10kw |

| Feeding Motor Power: | 3kw | Feeding Speed: | 6-35m/min |

| Condition: | New | Warranty: | 1 Year |

| High Light: | Automatic Multiple Rip Saw Machine 360mm,Solid Wood Panel Rip Saw Machine,Automatic Wood Rip Saw |

||

Product Description

MJ1435F Automatic Multiple Rip Saw

MJ1435F Multiple rip saw can process short wood materials of 360mm length with max thickness of 100mm. It is drived by a 22kw copper motor and a 3kw feeding motor.

Multiple rip saw is widely used for processing solid wood panel, MDF, particle board, plywood etc with high efficient and precision.

MJ1435F Multiple rip saw features:

-

This machine is a change of material, wood, wood core board is special, according to a preset size feed can saw cutting out much sticks, use of feeding wheel feed, and the upper and lower feed wheel, synchronous power feed.

-

Feeding wheel on a total of six groups, the wood of the pressure is controlled by a pressure cylinder material, visual wood hardness, free adjustment.

- Adopt frequency control of motor speed, feeding speed can be visualized feeding speed, easier to control the speed.

- The feed wheel feed, better than caterpillar feeding economic security, control and maintenance, material use pneumatic type, so even if the wood thickness change is big, also fixed pressure of material, material thickness range of the pressure is big, up to 35 mm.

- Electric adjustment of feeding wheel frame and lifting and blade spindle movements, easy to operate.

- Saw blade spindle can be dropped from saw blade saw blade working mesa, replacing saw blades.

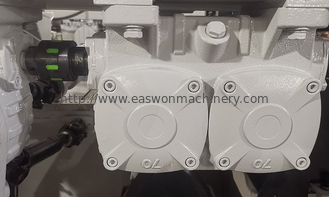

- Spindle use special alloy steel material, after heat treatment and precision grinding process for many times.

- High precision bearing spindle all USES large specification, load resistance, long service life.

- Security group, up and down and side safety barrier, protect the safety of operating personnel.

Specifications:

| Technical specification | Unit | MJ1435F |

| Saw blade size | mm | Ø250-Ø355 x Ø70 |

| Min. sawing length(intermittent/continuous) | mm | 550/360 |

| Max. sawing thickness | mm | 100 |

| Max. sawing width | mm | 300 |

| Total power | kw | 26.10 |

| Main spindle speed | r/min | 3600 |

| Main motor power | kw | 22 |

| Feeding motor power | kw | 3 |

| Elevating power of feeding mount | kw | 0.55 |

| Elevating power of saw mount | kw | 0.55 |

| Feeding speed | m/min | 6-35 |

| Dust outlet diameter | mm | Ø150 |

| Overall dimension | mm | 2670x1200x1500 |

| Net weight | kg | 1700 |

Multiple Rip saw details:

| Upper 4pcs and lower 2pcs driving wheel for feeding strong and powerfully | The high-torque reduction worm gear box is equipped with universal joints for the smoother feeding. |

| Multiple anti-rebound devices can effectively prevent wood from rebounding and imitating workers | The feeding speed is adjusted by frequency, and the pressing and main shaft lifting is adjusted electrically. |

| Equipped with laser marking device, wood sawing position is accurately aligned. | The automatic oil supply pump automatically supplies oil to the key parts of the transmission |

| The mist spray device extends the service life of the saw blade and minimizes the amount of water received by the wood. | Equipped with spindle sleeve, easy and quick to disassemble the saw blade |

Package and shipping:

The rip saw is packed by plywood case, which is suitable for FCL and LCL shipping.

After sales services:

1. Warranty: 1 year

2. Lifetime upgrades and consulting services

3. 24-hour servic hot line for consulting and solving the problems

4. Provide product design and solution within 24 hours

5. Supply operational manual and maintance manual in English.